Technology overview

Technical solutions - mousse-process

Vacuum

specialist

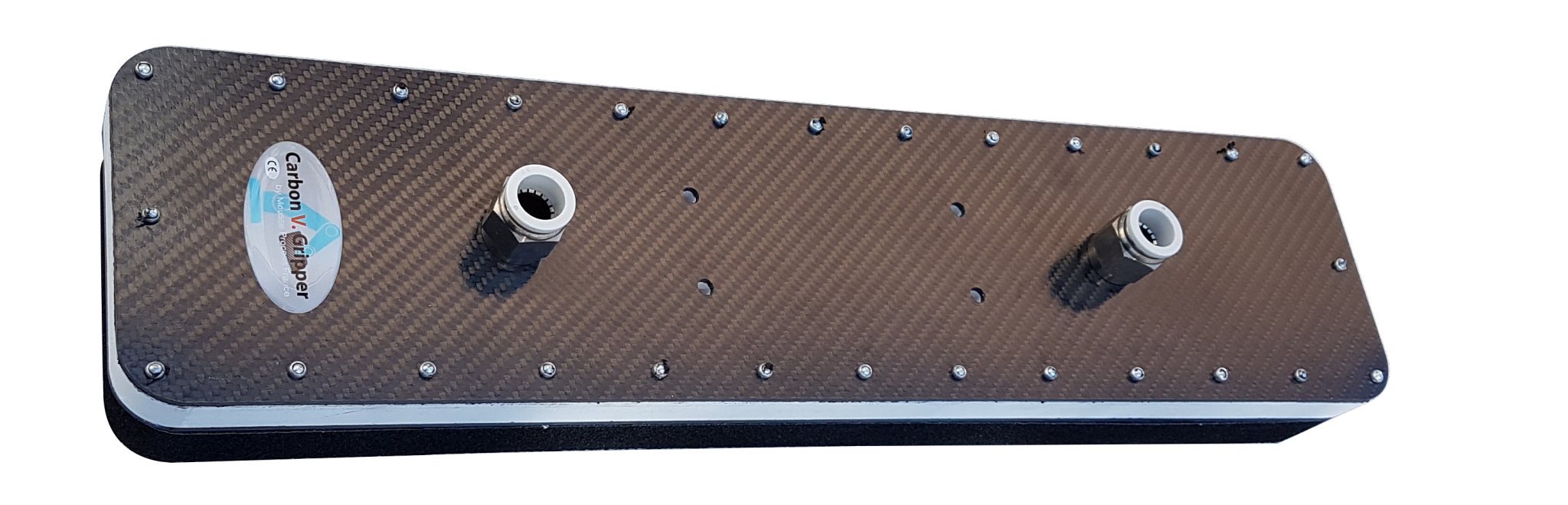

Mousse Process Gripper designs and manufactures new generation carbon technology foam vacuum grippers, custom built and suitable for almost all handling needs.

Our aim: To design innovative systems to meet the requirements of all handling processes. Our systems provide optimum efficiency, performance and reliability in automated handling processes: To increase productivity, while reducing costs and maintenance.

Our project methodology

The starting point of any project always takes into consideration all your technical data. We customize the gripper to the products being handled and to the speed and rate of your processes. Our design department determines the most suitable and relevant technology to handle your products and designs a customized tool. This design method eliminates any risk of malfunction and makes it possible to execute the most complex projects.

Mousse Process determines the most suitable gripper for your needs, by optimising the technical properties: lightweight, efficiency, turbine or venturi with lowest energy consumption. This design method enables our customers to make significant savings due to reliability and low energy consumption.

By optimising weight and power, Mousse Process Foam Gripper technology enables you to reduce the power consumption of your robots as well as the consumption of spare parts.

VACUUM LEVEL FORECAST TECHNIQUES

Mousse Process has developped the VLF technic (Vacuum Level Forecast). This allows the control of the vacuum level and ensures the reliability of product gripping. The VLF technique makes it possible to anticipate and predict the date for foam changing by checking the vacuum thresholds. It is not necessary to wait for products to drop before replacing the foams, nor is it necessary to replace the foams at estimated intervals when they are still serviceable. VLF technology means the foams are replaced at the optimum time, thus significantly reducing maintenance costs and unplanned production downtime.

Our grippers

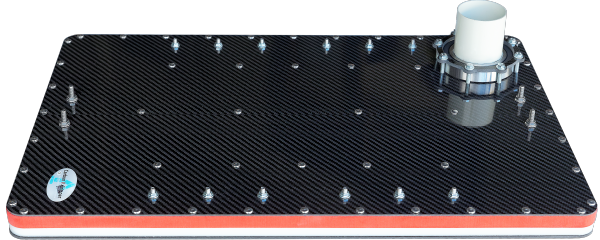

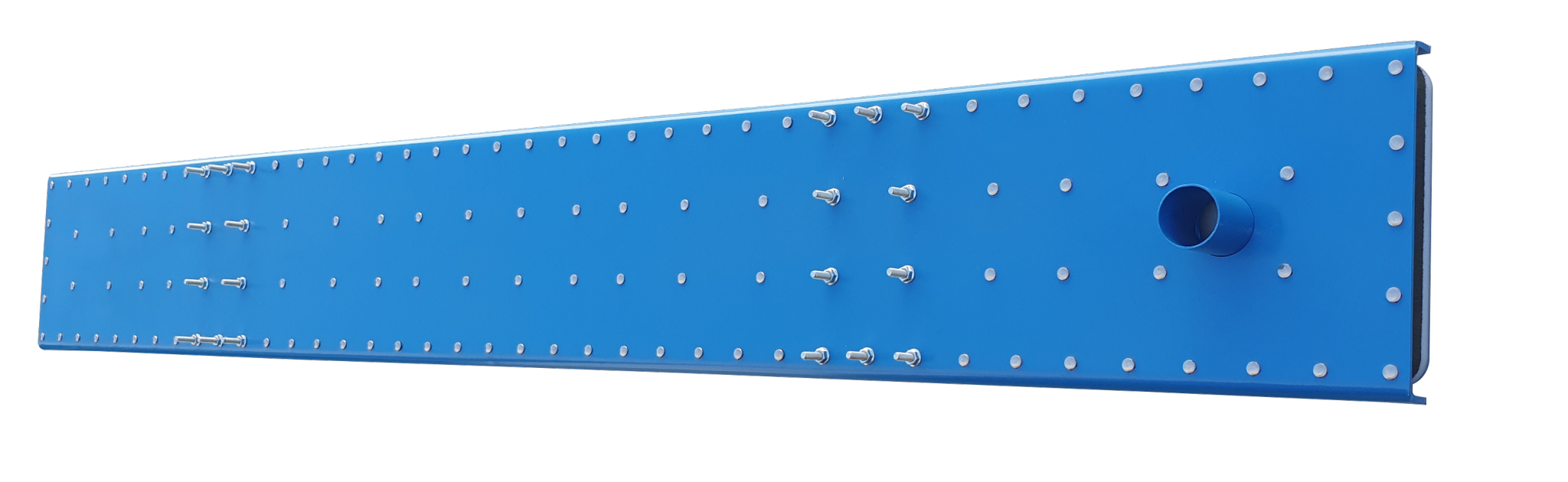

PMSC – VALVELESS FOAM GRIPPERS (WITH CALIBRATED NOZZLES)

Technical description

With valveless technology, the grippers can work in all directions, with almost instantaneous gripping time. It is the most economical and lightest solution. A calibrated nozzle above each foam cell optimises the power of the turbine or venturi.

Suitable applications?

The valveless foam grippers are suitable for gripping cardboard boxes and various industrial products. The foam adapts to the shape of the product being handled. They are efficient when the product covers more than 70% of the gripper.

PMBC – BALL VALVE FOAM GRIPPERS

Technical description

A ball valve is placed in the suction channel above each foam cell.

Gravity ball valves automatically close the suction channel of each uncovered foam cell.

When there is no product under the foam, the air velocity creates an aerodynamic force Fa = ½ ρ S V² Cx which lifts the ball and closes the seat of the suction channel. When the product to be handled covers the foam cell, the air velocity is insufficient and the force of gravity Fg = mg, is greater than Fa, pulling the ball down and opening the suction channel.

Therefore, 100% of the vacuum generator’s power is used for gripping the products.

Suitable applications?

Foam grippers with valves are designed for handling porous and deformed products with uneven surfaces and when the product can only cover a small proportion of the gripper.

The PMBCs allow the gripping of horizontal products, and handling products in full or partial layers. The use of the force of gravity to open the valves does not allow the gripper to be used reliably at angles greater than 45° or with accelerations reaching 10 m/s².

PMMC – MULTIDIRECTIONAL VALVE FOAM GRIPPERS

Technical description

Unlike the gravity valves, multidirectional valves can operate in all directions. They are designed with a diaphragm, which opens and closes to allow or stop the air flow. This technology is not dependent on gravity, this allows the diaphragm to open and close in all directions.

Suitable applications?

The PMMCs have the same applications as the PMBCs but they can work in all directions: horizontal, vertical, upside down, and pick up or place in any orientation. These grippers can be used with robots with accelerations higher than 1G.

PMAD – AERODYNAMIC FOAM GRIPPERS

Technical description

The air speed generated by the turbine creates an aerodynamic force Fa=1/2ρSV²Cx which is directly transmited to the product being handled. Mousse Process Gripper precisely determines the appropriate technologies and calculates the optimum power for gripping the product.

The aerodynamic grippers are both very simple to manufacture and high tech. They often require a specific study and wind tunnel testing to determine the Cx of the handled product.

Suitable applications?

Aerodynamic grippers are particularly efficient for handling light, loosely packed, low-density or small products: paper, empty cartons, small metal or plastic parts, very porous materials… They allow the handling of products that seem to be impossible to grasp by more elaborated vacuum grippers.

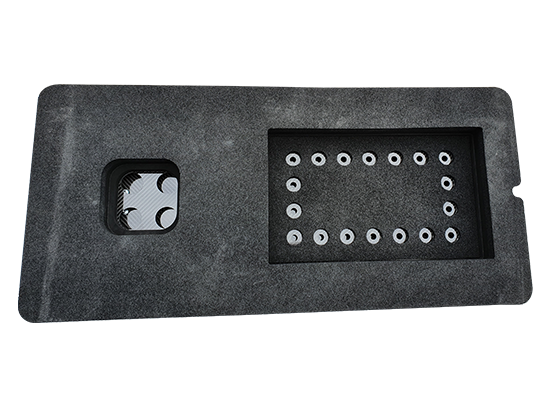

PMGC – WASHER VALVE FOAM GRIPPER

Description technique

The PMGC Grippers are equipped with multi-hole foams. Each foam hole is connected to a large suction channel and a self-closing valve consisting of a stainless steel washer. This large valve permits a high airflow including dust or dirt.

The valve washers are relatively unaffected by severe operating conditions.

The PMGCs allow very fast pick up times thanks to the PFD (Parallel Flux Diffusion) technology. The valves do not close in series, but simultaneously due to the parallel technology. This exclusive technology also allows a reduction in the power required by the vacuum generator.

Suitable applications?

PMGCs are designed for handling heavy and heavily soiled products: wood with resin, concrete, bricks, products with soil and debris, high humidity, and frost.

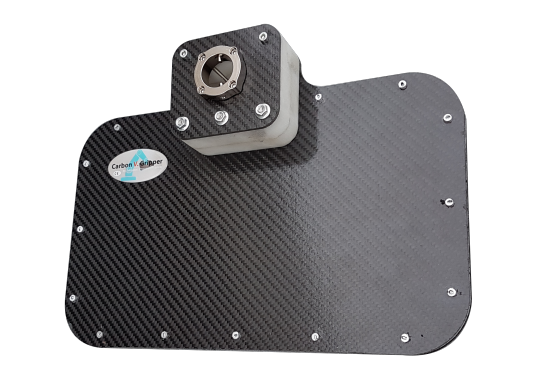

PM2V – SINGLE SUCTION CUP FOAM GRIPPERS

Technical description

PM2V are made of a carbon plate with a peripheral foam. Shapes and dimensions are customized. This technique is simple, efficient and economical.

Suitable applications?

This technology is simple, suitable for handling flat products that cover 100% of the gripper such as wood panels, metal sheets or glazing. It is an effective alternative to traditional rubber or nitril suction cups. When the shape is irregular, when heavy weights are being handled (concrete), or when the surface is rough, this technique is more efficient than traditional suction cups.

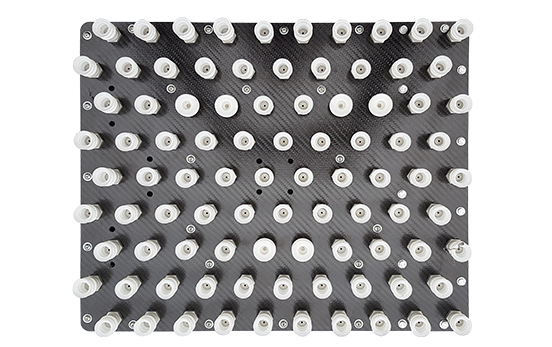

PM3V – MULTI MICRO SUCTION CUP FOAM GRIPPERS

Technical description

The PM3V consists of a carbon box which is also the suction cup support. A multiple array of small suction cups placed under the box effect product gripping. This technique can be associated with the PMBC, PMSC and PMMC. The usual foam seal is replaced by a number of small suction cups.

The diameter of the suction cups and the pitch between the cups are customized to suit the product.

Suitable applications?

PM3V are suitable for gripping relatively smooth products. The suction cup life reduces the frequency of maintenance. This technology is suitable for very high speed robots. It is suitable for handling non-dry food products (e.g. meat in direct contact).

PMVC – BELL-SHAPED FOAM GRIPPERS

Technical description

PMVC grippers consist of a carbon support and a Bell shaped foam .

Suitable applications?

Foam bell grippers are suitable for the handling of powdery or bulk products in bags, such as bags of cement, flour, seed, dried fruit, etc.

Need some information?

Would you like to know more? Our team is at your disposal to answer your questions, to advise you and accompany you in your projects!